Electrofusion

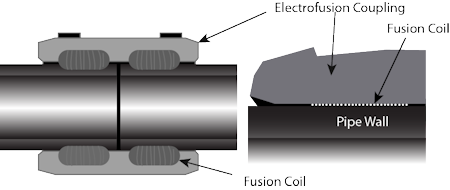

The main difference between conventional heat fusion and electrofusion is the method by which the heat is applied. In conventional heat fusion (butt, saddle and socket) joining, a heating tool is used to heat the pipe and fitting surfaces. The electrofusion joint is heated internally, either by a conductor at the interface of the joint or by a conductive polymer. Heat is created as an electric current is applied to the conductive material in the fitting. PE pipe to pipe connections made using the electrofusion process require the use of electrofusion couplings.

Typical Electrofusion Joint

REFERENCES

- MAB Generic Electrofusion Procedure for Field Joining of 12 Inch and Smaller Polyethylene (PE) Pipe

- TN-34 was replaced MAB-02

- MAB-02 2017 - MAB Generic Electrofusion Procedure for Field Joining of 14 Inch to 30 Inch Polyethylene (PE) Pipe

- PPI PE Handbook, Chapter 9

- ASTM F1055 Standard Specification for Electrofusion Type Polyethylene Fittings for Outside Diameter Controlled Polyethylene and Crosslinked Polyethylene (PEX) Pipe and Tubing

- ASTM F1290 Standard Practice for Electrofusion Joining Polyolefin Pipe and Fittings